Helping our customers achieve efficient, low-cost, quality manufacturing is our goal. Uway offers several extruder designs to achieve the production and quality levels that you seek. As your valuable partner, we are here to assist you in choosing the most accommodating system for your needs.

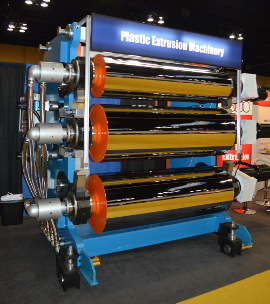

Single Screw Extruders

Single screw extrusion is the most widely used screw in polymer sheet and film manufacturing. They are capable of efficiently producing most polymer materials. Single screw extruders can handle a large variation of operating conditions while performing competently.

Generally, in a 120mm configuration, single screw extruders are the easiest extruders to consistently operate in a wide variety of environments. For general purpose extrusion, single screw systems are recommended.

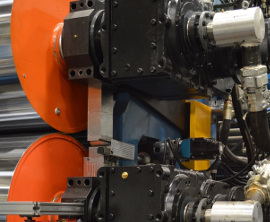

Conical Twin Screw Extruders

This specialized extruder design can offer the most economical system for the adequate production of PVC and WPC. Currently, we are very successful in operational outputs up to 6000 kgs per hour while using conical twin screw extruders.

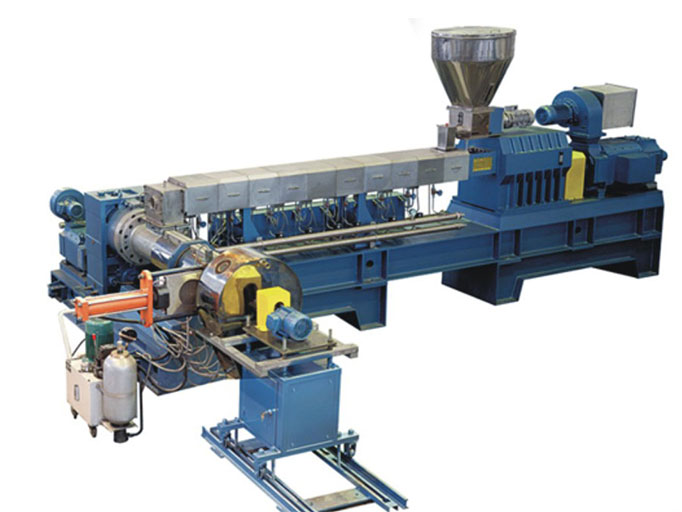

Parallel Twin Screw Extruders

These systems are commonly deployed for processing PET, PLA, TPU, EVA, PVB and PVC. Parallel twin screws offer higher production rates within a single extrusion system. This system offers the best melt and pressure environment for PVC and WPC.

The linear combination of twin screw extruders and a single screw extruder are used for the production of high-quality thermoforming sheet at more than 1000 kgs/hr especially for undried PET and polymer formulations rich with additives.