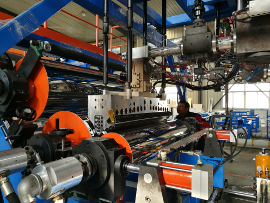

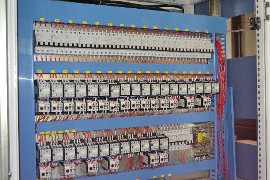

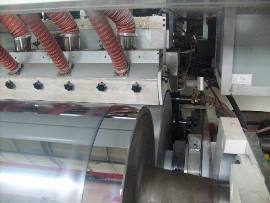

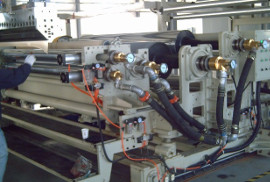

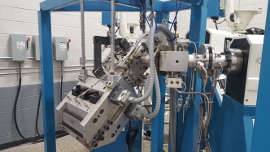

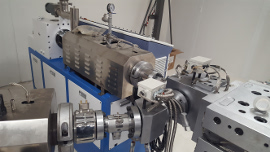

Extrusion Systems

We offer the most complete custom extrusion systems.

We offer the most complete custom extrusion systems.

Copyright © 2026 Uway Extrusion. all rights reserved.